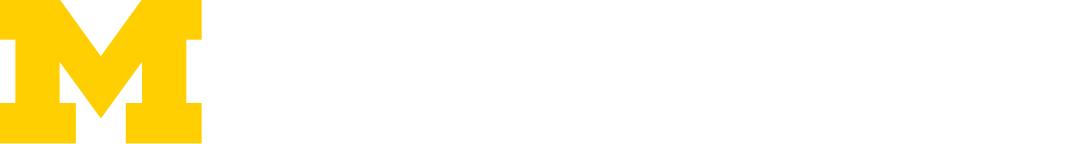

Nanofabrication

We develop various self-assembly and guided self-assembly techniques for nanofabrication.

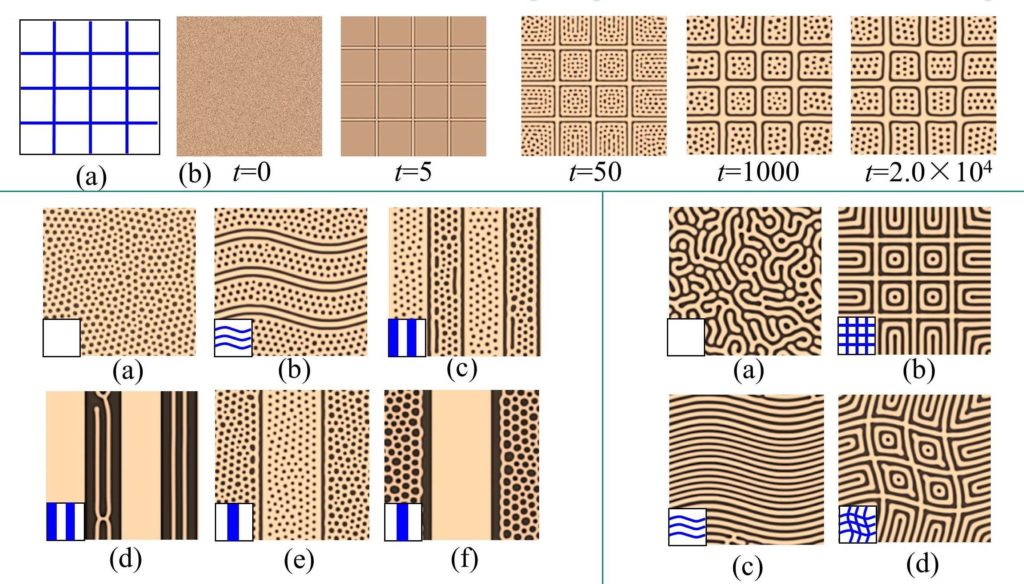

Joining of dissimilar materials

Friction stir welding (FSW) is a key enabler for joining dissimilar materials. While joining dissimilar materials with FSW offers great potentials for achieving structural lightweighting and engineered properties, it is difficult to produce robust and reliable aluminum/steel joints due to their mismatch in physical properties and poor metallurgical compatibility. The major problem is the formation of hard and brittle intermetallic phases, which could lead to cracking and reduce the joint strength. The high heating/cooling rate, temperature gradient, and localized shear deformation field make the FSW process highly non-equilibrium. The traditional intermetallics phase diagram based on bulk materials applies to equilibrium conditions only, and provides no information on growth kinetics. We aim to develop multiscale models and simulation techniques to predict the size, orientation, and distribution of intermetallics when joining dissimilar materials, such as aluminum and steel, and predict the change of microstructures during the FSW processing.